research at dit

pioneering & vibrant

about campus parsberg / lupburg

From the initial idea to the ambitious research project - at the Technology Campus Parsberg/Lupburg, the Deggendorf Institute of Technology and the East Bavarian University of Applied Sciences Regensburg (OTH) combine their expertise in the fields of materials science, manufacturing technology and digitalisation. Here, research, teaching and training is carried out in five laboraties, numerous training rooms, a workshops and office space for up to 40 employees on an area of 2,000 square metres.

For the transfer of knowledge and as a contribution to the business location, the campus cooperates with companies in the surrounding area as well as throughout Germany. These cooperations range from joint research projects as an external research and development department, to support in applying for research funds, to a wide range of services, such as training courses and workshops for companies, rental of seminar, training and work rooms as well as equipment, etc.

In addition to academic staff and students, you will also meet young entrepreneurs and start-ups from the Digital Incubator on campus. At the incubator, the innovative minds of the region create new business ideas are supported by a Bavarian-wide network. Start-ups can present themselves at regular events and have the opportunity to network with established companies in the region.

management

A management committee was set up to manage the inter-university Technology Campus. The scientific management is carried out by three professors. One professor from the Deggendorf Institute of Technology, Prof Dr Andrey Prihodovsky, and three OTH professors, Prof Dr Stefan Hierl, Prof Dr Ulf Noster and Prof Tobias Laumer. Anton Schmailzl is responsible for the operative management. A total of around 30 people work at the campus in Parsberg-Lupburg.

main areas of research

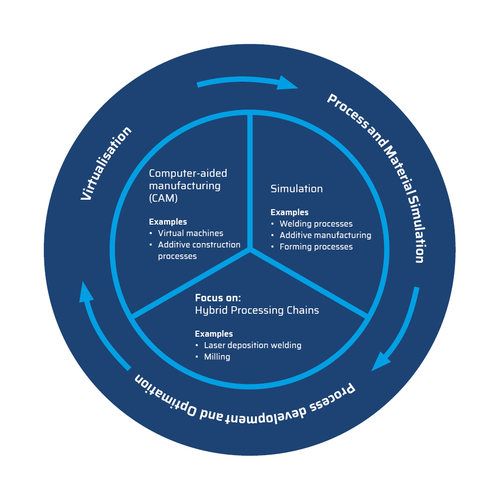

DIT pursues the following research priorities at the Technology Campus Parsberg / Lupburg (Illustration in German):

The focus is on both long-term research projects and short-term service and contract research projects. In detail the following is carried out:

- Research projects with companies, institutes and universities, often with public funding

- Contract research for companies in the district of Neumarkt, in particular for small and medium-sized enterprises (SMEs) and start-ups

- Consulting for innovation projects

projects

equipment at campus parsberg / lupburg

At the TC Parsberg / Lupburg, which spans several universities, equipment is available in the following areas:

- Material analysis (micro- and macroscopes, photo documentation workstation, automatic hardness testing equipment, vibration test bench, metallography, tensile-compression testing equipment, workstations for residual stress measurement)

- Laser material processing (four laser protection cabins with corresponding safety technology)

- Additive manufacturing (several plastic 3D printers)

- Mechanical manufacturing processes (CNC lathe, pillar drilling machine, belt grinder, band saw, CNC milling machine)

In addition to the equipment, various software products are also available, which in particular enable the simulative mapping of manufacturing processes (CAD/CAM/PLM programmes, FEM programmes, etc.).

publications

Below is an overview of the publications of the members of the Technology Campus Parsberg.

Schmailzl, A.; Schröcker, K.; Gansauge, L.; Prihodovsky, A.: Potenziale von hybriden Fertigungsprozessketten. In: Baier, W. (Hrsg.): 1. TRIOKON 2019 – Die ostbayerische Transferkonferenz für Wirtschaft, Wissenschaft und Gesellschaft, Regensburg (2019).

current job openings

We are constantly looking for experts from various fields such as mechanical engineering, physics, computer science, industrial engineering and many more.

we're currently looking for:

Current job openings can be found in our University portal.

Unsolicited applications are best sent to: sekretariat-tcpl@th-deg.de

student research projects and theses

Innovative workplaces are available at TC Parsberg / Lupburg for graduates and young scientists.

In the following you will find announcements for student research projects and theses.

We are also happy to accept unsolicited applications for the research areas as shown in the figure at the beginning.

- Development of FEM models for the time-efficient calculation of residual stresses and component distortion during machining

- Design of experimental designs and performance of numerical experiments

- Evaluation and analysis of the calculation results

- Validation of the simulation

- Programmes: MSC.Marc/Mentat, MATLAB

Contact person: Johannes Käsbauer, M. Sc.

- Development of thermos-mechanical models for the time-efficient simulation of additive manufacturing processes such as laser powder classing (LMD) and wire cladding (WAAM) for the prediction of component properties, residual stresses and distortion

- Design of experimental designs and performance of numerical experiments

- Evaluation and analysis of the calculation results

- Validation of the simulation

- Programmes: MSC.MARC/Mentat, MATLAB

Ansprechpartner: Maximilian Fichtl, M. Sc.

During the production of components in aluminium die casting, strong changes in temperature occur on the tool surfaces within a short period of time - so-called thermal shocks. Due to the thermal expansion, these cause mechanical stresses that lead to cracks and thus reduce the service life of the tools. Numerical simulation offers the possibility to test new concepts to improve the behaviour of the tools during thermal shocks.

Activities:

- Development of a simulation model to calculate the mechanical stresses caused by thermal shocks in die casting tools

- Simulation-based determination of the effects that cause stresses and analysis of improvement potentials

- Development of concepts to improve tool life time

- Implementation of the new concepts in the simulation model and execution of simulations

- Evaluations of the new concepts by comparison with conventional tools.

Contact: Johannes Käsbauer, M. Sc.

The components to be analysed were manufactured using various DED processes (laser metal deposition, wire arc additive manufacturing and cold gas spraying). The properties of the components are subsequently compared with available simulation results and serve to validate these results.

Activities:

- Analysing the chemical composition

- Measuring and analysing hardness curves

- Preparation of microsections and microstructural images

- Carrying out adhesion tests

- Carrying out heat treatments

- Carrying out tensile tests

- Evaluating and documenting all results

- Programmes: MATLAB, SpArcfire

All experimental work must be carried out at the Technology Campus Parsberg-Lupburg and is only possible in presence.

Contact: Korbinian Schröcker, M. Eng.

The production of metallic thin films is of grear technological importance of microelectronics and related fields. Thin films of copper serve as interconnect material in current printed circuit boards due to their low electrical resistance, low specific weight, low production cost and ease of fabrication. Thin-film materials can be adapted to the required demands of the respective application by adjusting their properties during processing. Grain morphology, texture and stress are important aspects of the thin film properties. In the present work, the primary aim is to investigate influencing conditions for thin-film deposition and the surface properties of the substrates in order to improve the adhesive strength between different materials and to avoid detachment. The higher the adhesion strength, the longer the lifetime of the device to counteract premature delamination under both higher loads and contact pressures and to assess the overall reliability of the system.

Activities:

- Fabrication of multilayer thin film structures of atmospheric plasma CVD thin film deposition

- Structural and chemical investigations by scanning electron microscopy and EDC

- Adhesion measurement of metallic thin films by pull method

- State of the art of copper-ceramic plasme CVD thin film deposition systems

Contact: Dr Himano Jain

Laser powder cladding (LMD) and wire arc additive manufacturing (WAAM) are established processes in additive manufacturing with metals. These processes are based on the fact that the desired component geometries are built up by superimposing a large number of weld seams.

For a resource-efficient development of suitable machining strategies, these manufacturing processes are mapped and investigated in numerical simulation models based on the finite element method. Since the production of a component often requires weld seams several metres long, this results in very long calculation times, which is why the use of simulation in process design is currently little used. In order to make use of the advantages of numerical simulation in the design of LMD and WAAM processes, it is of interest to reduce the calculation time without causing a significant loss of accuracy in the calculation results. In order to achieve this, for symmetrical components it is possible to investigate the build-up process on a quarter or half model and thus simplify the calculation. Since only a fraction of the component is modelled, the boundary conditions have to be adapted accordingly.

It is to be tested how the boundary conditions are to be adjusted with this new approach in order to avoid an impairment of the calculation results. Likewise, it is to be tested how large the resulting computation time savings are.

Activities:

- Conceptual design of different components for the test calculations

- Modelling of the structure of the components without simplifications and calculation of the process sequences as reference simulations

- Development of a strategy for the adaptation of the boundary conditions with geometric simplification of the components

- Modelling of the structure of the geometrically simplified components with adapted boundary conditions and execution of the thus simplified simulations

- Evaluation of the approach with regard to calculation time reduction and accuracy of the calculation results by comparing the reference simulation and the simplified simulation.

Contact: Johannes Käsbauer, M. Sc.

Simulations are an integral part of modern development processes and serve as a basis for a multitude of decisions. The number of software solutions available on the market is as diverse as the areas of application in which they can be used. For this reason, the selection of the right software packages is increasingly coming to the fore in order to not only have the possibility of making forecasts and calculations, but also to achieve this goal in the best possible and most efficient way.

The working group of the Deggendorf Institute of Technology at the Parsberg-Lupburg technology campus specialises in the field of digital manufacturing. For this purpose, simulation serves as a decisive tool for predicting material properties, developing processes, carrying out optimisations and virtualising processes. A variety of software solutions are available for these areas of application. The content of this thesis is to develop a benchmark method and simulation models, which, applied to the respective field of application, can compare the available software packages with regard to their "efficiency" (e.g. programming possibilities, interfaces, solver performance ...).

Contents:

- Classification and delimitation of the areas of application for software solutions used in the field of the finite element method (FEM).

- Definition of the requirements for a method for the benchmark of software packages

- Definition of evaluation criteria

- Development of the method for the comparison of software packages

- Development of cross-programme benchmark models

- Definition of a benchmark procedure

- Implementation of benchmarks and comparison of individual software packages

Programme examples:

MSC Marc, Altair Hyperworks, Simufact Welding, DYNAmore LS-DYNA, Siemens Simcenter.

Contact: Maximilian Fichtl and Manfred Hiermann

directions

|

Technology Campus Parsberg-Lupburg Am Campus 1 Telephone: +49 9492 8384 0 E-Mail: sekretariat-tcpl@th-deg.de |