Research at DIT

Pioneering & Vibrant

The research centre "Modern Mobility" at the Technology Campus Plattling is divided into two superordinate research areas. In the area of technology development for modern mobility and the area of computed tomography-based measurement technology for real-time measurement of complete vehicles.

About the Campus Plattling

Since autumn 2020, the TCP has been located in the heart of the former railway town of Plattling. The TC Plattling is divided into two research areas: ‘Modern Mobility’ and ‘Real-Time Computed Tomography’. Modern Mobility uniquely combines the relevant core research fields for electrified mobile autonomous systems in one location. The Robo CT for the analysis of complex and large-volume 3D objects, in its current form and coupled with the existing expertise, represents a prominent facility in the field of research. Through the complementary cooperation of the individual research groups with renowned research institutions and chairs, the TCP is advancing to become a recognised institution for applied research.

Expertise

The Power Electronics Department headed by Prof. Dr.-Ing. Otto Kreutzer conducts research on the following topics:

- Power electronics for e-mobility (motor vehicles, rail vehicles, etc.)

- High-performance charging stations with high efficiency (in combination with storage solutions)

- DC/DC conversion in the context of electrolysers/fuel cells and

- Smart grid & renewable energies

- AC/DC conversion in 16.7 and 50 Hz networks

- DC/AC conversion in drive converters for fuel cell systems and battery-electric drives

The central task is the development and optimisation of power electronic converters specific to the respective application.

Research work

Analyses, calculations, simulations and the creation of circuit diagrams and assembly plans form the basis of the research work.

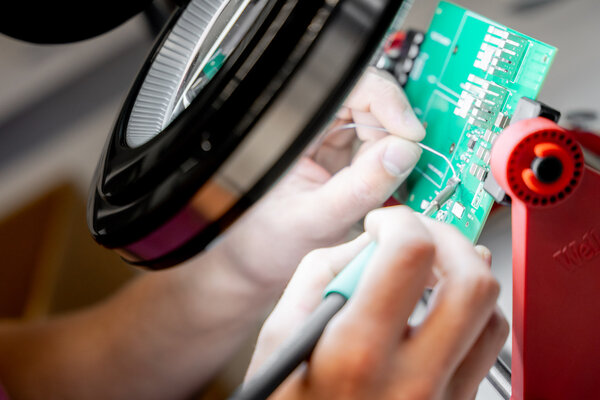

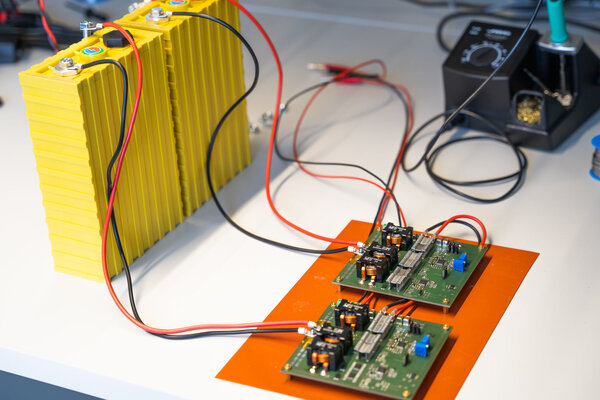

The prototypes are then manufactured. A small workshop for mechanical work, a winding area for the in-house production of wound goods and a power electronics laboratory for all electronic activities are available for this purpose.

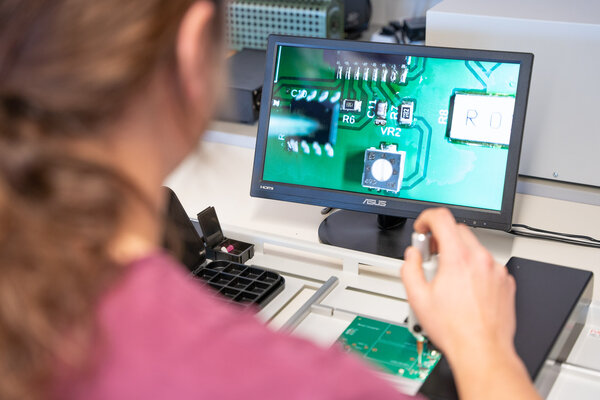

In the picture: Assembly of SMD components for a step-up converter

In the picture: Assembly of the wired components

In order to achieve high circuit efficiency, passive components, such as wound components, must also be manufactured in-house to meet the required parameters.

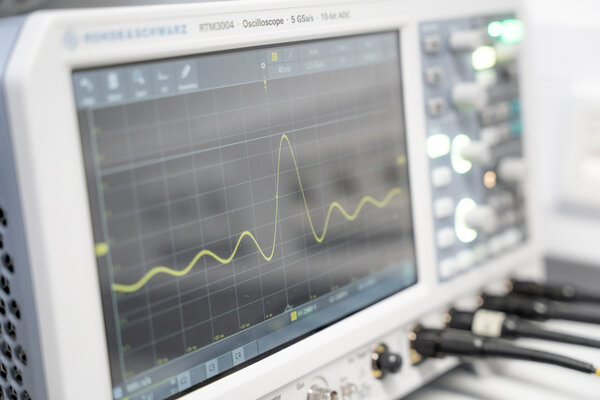

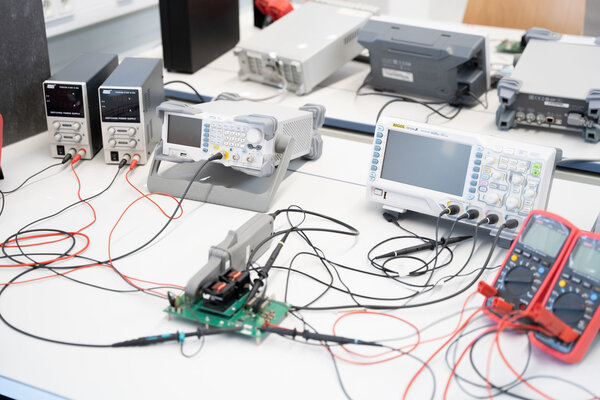

Once the circuits have been completed, they are commissioned and all parameters are tested and measured. In power electronics, measuring efficiency is particularly important.

Finally, the research work is tested in practice.

In the picture: Intelligent single-cell-based battery management system for a multi-level battery system

Exemplary, current challenges

- Development of a self-sufficient system with solar energy feed-in and energy storage in the form of hydrogen

- Development of a burying DC fast charging station that can be supplied from the traction power network (15 kV 16.7 Hz) (Rail-HPC)

- Direct feed-in of electric vehicles from photovoltaic systems (direct PV)

- Various contract research projects

Overview of equipment

- 4-quadrant AC network simulator

- Bidirectional DC supplies

- SMD assembly station (stencil printer, automatic placement machine, reflow soldering oven, etc.)

- Vector network analyser

- Saturation current measuring device

- Partial discharge tester

- Thick wire bonder

- High-voltage insulation measuring device

- etc.

The complete overview can be found at: Power electronics equipment Plattling

The working group led by Prof. DI Dr.techn. Michael Sternad focuses on the following research topics:

- High-power lithium-ion batteries

- Ageing effects, including during fast charging of lithium-ion batteries

- Lithium metal batteries with electrolytes based on ionic liquids

- Novel electrode morphologies (e.g. using laser patterning)

Publications by Prof. Sternad: Google Scholar Web of Science ORCID

Selected publications

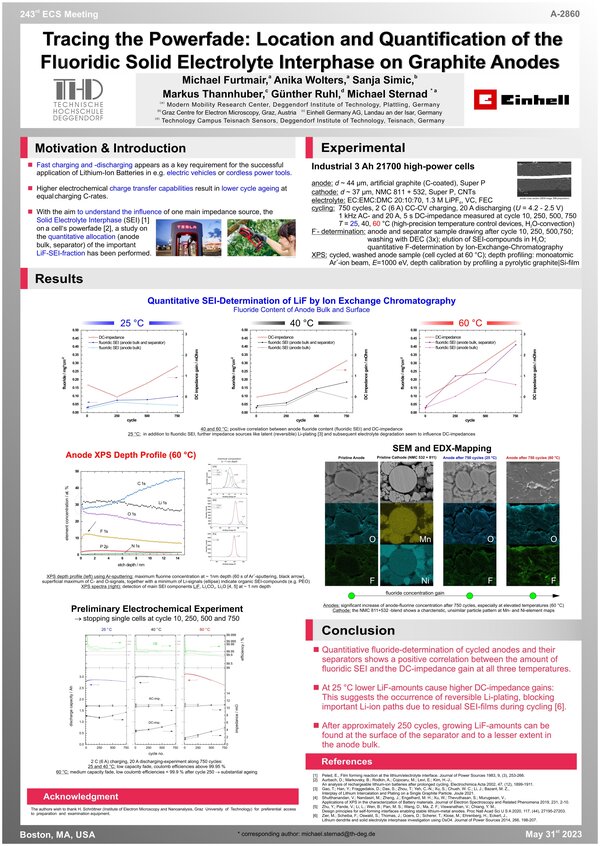

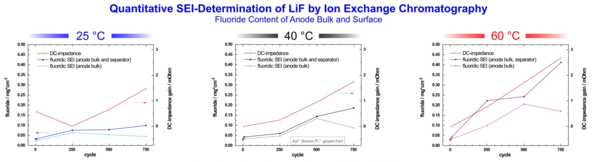

- Tracing the Powerfade: Location and Quantification of the Fluoridic Solid Electrolyte Interphase on Graphite Anodes (243rd ECS-Meeting, Boston, 2023)

Positive correlation between the strength of the fluoride SEI and the direct current cell impedance (DC impedance) of a 21700 cell

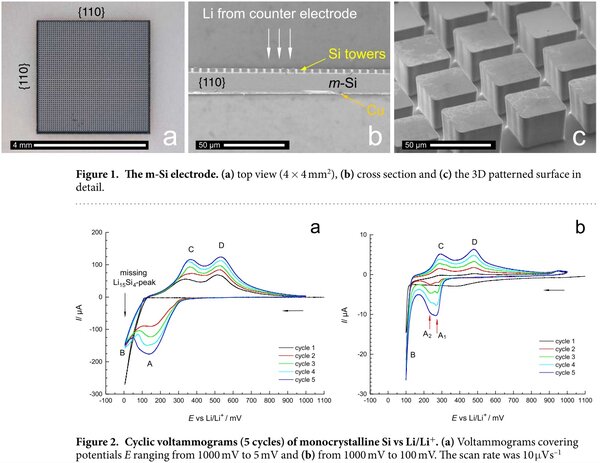

- A Lithium‐Silicon Microbattery with Anode and Housing Directly Made from Semiconductor Grade Monocrystalline Si (Advanced Materials Technologies, 2021, Collaboration with Infineon Technologies Austria AG, published with funding from the European Union (European Regional Development Fund, ERDF)

![]()

Fully integrated lithium-silicon microbattery, single-crystal silicon as anode and housing material

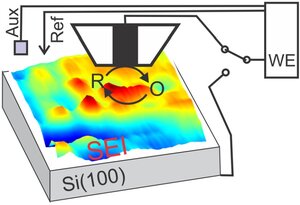

- Nascent SEI-Surface Films on Single Crystalline Silicon Investigated by Scanning Electrochemical Microscopy (2019, Zusammenarbeit mit AG Prof. G. Wittstock, Uni Oldenburg)

Investigation of surface layer formation (SEI) on a battery anode made of single-crystal silicon using SECM (scanning electrochemical microscopy)

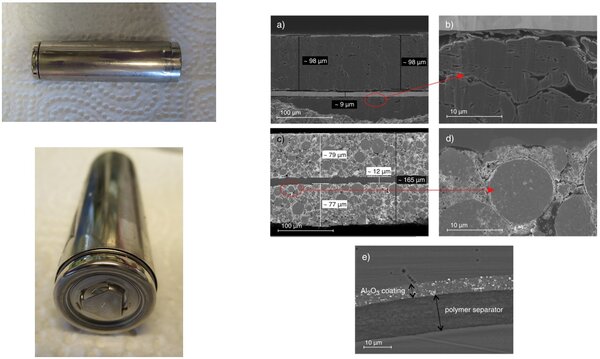

- Aging of Tesla's 18650 Lithium-Ion Cells: Correlating Solid-Electrolyte-Interphase Evolution with Fading in Capacity and Power (2017, collaboration with AVL List GmbH)

Charakterisierung einer 18650-Tesla-Zelle, Studium des Alterungsverhaltens bei unterschiedlichen Temperaturen und C-Laderaten

- The microstructure matters: breaking down the barriers with single crystalline silicon as negative electrode in Li-ion batteries (Scientific reports, Nature Publishing Group, 2016)

Study of the fundamental electrochemical properties of single-crystal silicon (100) during lithiation

Available methods and equipment

Working under protective gas

- MBRAUN Labmaster Pro SP Glovebox (argon, < 0.5 ppm H2O)

Preparation of laboratory test cells (Swagelok cells, button cells, pouch cells)

- Fritsch PULVERISETTE 7 planetary mill (slurry preparation)

- Proceq ZAA 2300 automatic film drawing device (squeegee 80-100 mm)

- Fine vacuum drying line (p = 10-2-10-3 mbar), Büchi glass furnaces

- Metrohm 831 Karl Fischer coulometer with 860 KF headspace oven

- Mettler XSR105DU analytical balance (0.01 µg resolution)

- Swagelok, button and pouch cell production

Electrochemical characterisation of laboratory test cells

- Biologic MPG 2 potentiostat, 2 x 16 channels

- Biologic SP 50 potentiostat, 1 channel

- Memmert temperature chambers (25, 40, 60°C)

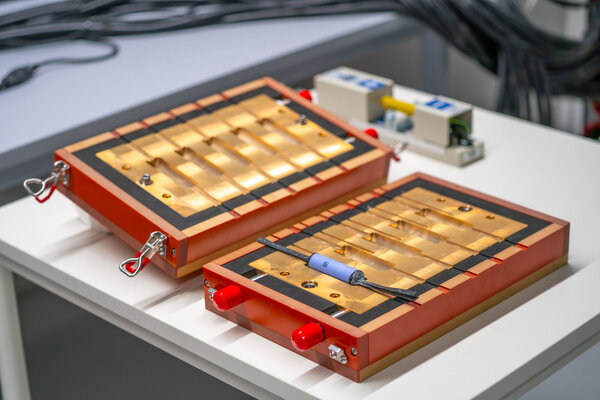

Electrochemical characterisation of industrial cells (e.g. 21700)

- Arbin LBT21084HC battery cycler, 40 channels, 0-5 V, 60 A

- High-precision temperature control device for 18650/21700 cells (T +/- 1 K under 20 A load)

Chemical analysis, imaging techniques and other equipment

- Agilent Cary 630 FTIR/ATR spectrometer (diamond and Ge crystal optics)

- Agilent 8860/5977C GC-MS system

- Thermo Fisher NEXSA X-ray photoelectron spectrometer (XPS, TC-Teisnach)

- Zeiss Ultra 55 scanning electron microscope, EDAX EDS detector

- ZEISS METROTOM computer tomograph (5 µm spot size)

- Rotofix 32 A tabletop centrifuge (electrolyte sampling from battery cells)

- Access to Hg porosimeter, Dionex ion exchange chromatography, flame and graphite tube atomic absorption spectrometry (AAS), etc.

Glovebox, fine vacuum drying line installed in the fume hood

Arbin high-current cycliser

Copper heat exchanger for precise thermostatting of battery cells during testing

Manufacture of electrodes: coating of current conductor foils with so-called ‘slurry’ (viscous active material mixture)

Laboratory calander for compacting the dried active material coating with a finished electrode web in the foreground

Services

Qualification of battery cells:

Before a cell is used in a specific product, it is usually the responsibility of the cell manufacturer to prove the quality and safety of its cell to, for example, an appliance or automobile manufacturer (to ‘qualify’ it).

Typical battery qualification includes:

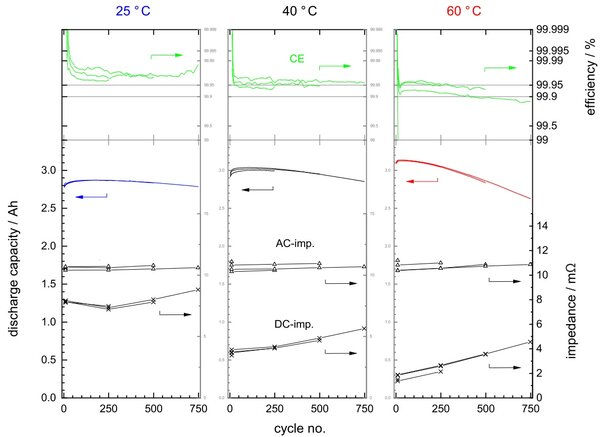

- Cycling the cells at 25, 40 and 60 °C, 750 cycles under the charging and discharging conditions specified by the cell manufacturer (according to the spec sheet). Electrical and electrochemical parameters such as discharge capacity, coulombic efficiency (charge efficiency) and AC (1 kHz) and DC (5 s, 20 A) impedance are recorded.

- Opening of one selected cell per temperature under protective gas in a glovebox (‘post mortem analysis’):

a. Assessment of the macroscopic condition, especially of the anodes (with regard to lithium plating) and the separators (short circuits or thermal anomalies, hot spots)

b. Detailed photo documentation of all cell components (anodes, cathodes, separators, cell housings and safety devices

c. Recording of the geometric parameters of the electrode tracks and the separator, including the active material layer thicknesses

d. Macroscopic examination of the cell's safety devices (e.g. the CID or the PTC)

- Reporting with an expert opinion on the quality and safety of the tested cell design as a basis for decision-making for potential buyers of the cells

The experts at AG Sternad are happy to answer any questions you may have about battery qualification!

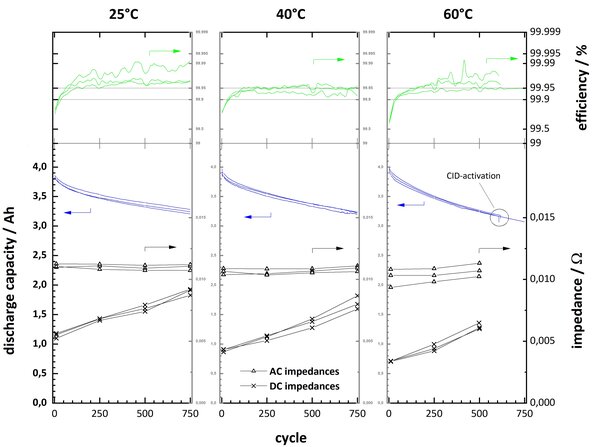

Example of the results of a cycling experiment over 750 cycles (750 charging and discharging processes) at 25, 40 and 60 °C:

Electrochemical experiment (cycling) of an industrial 3 Ah 21700 cell type under temperature-controlled conditions

If any problems occur in the battery cell during the experiment, which lasts approximately 4–5 weeks, the test procedures are automatically interrupted:

Cycling of nine (three per temperature) Samsung INR21700-40T, 4000 mAh cells, activation of the cell internal circuit breaker (‘CID activation’) due to excessive internal cell pressure at 60 °C

In order to assess the condition of the electrode coatings and the safety status of the cells after 750 cycles, one cell per temperature is partially discharged and opened under protective gas (argon) in a glovebox (post mortem analysis):

Opening and dismantling a 21700 cell under protective gas (left) and macroscopic examination of the separator and electrode surfaces (right)

Current projects

- Research and service projects with corporate partners such as Einhell Germany AG and the DRÄXLMAIER Group.

- FestBatt – Cluster of competence for solid-state batteries

Completed projects

OptiStore - Optimised energy storage systems for sustainable utilisation (European Union, ERDF)

The Autonomous Driving and Driver Assistance Systems department, led by Prof. Thomas Limbrunner, conducts research into autonomous systems and driver assistance systems. The general objective of the research group is to conduct applied research across the broad spectrum of autonomous systems.

The focus is primarily on the following areas:

- (Environmental) sensor technology

- Algorithms for object discrimination

- Object tracking

- Anomaly detection

- META data generation/analysis (including using artificial intelligence)

- Overall system architecture of autonomous systems

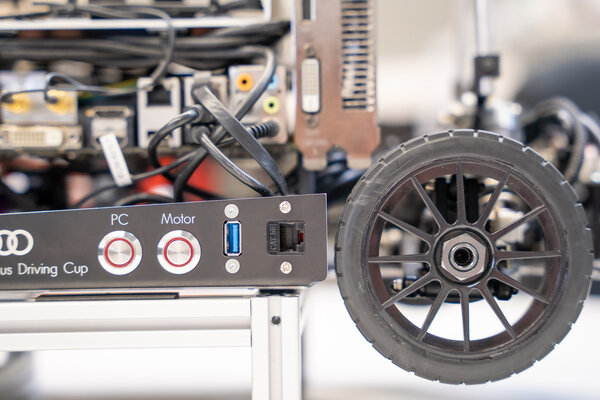

Model scale test platform

Research work

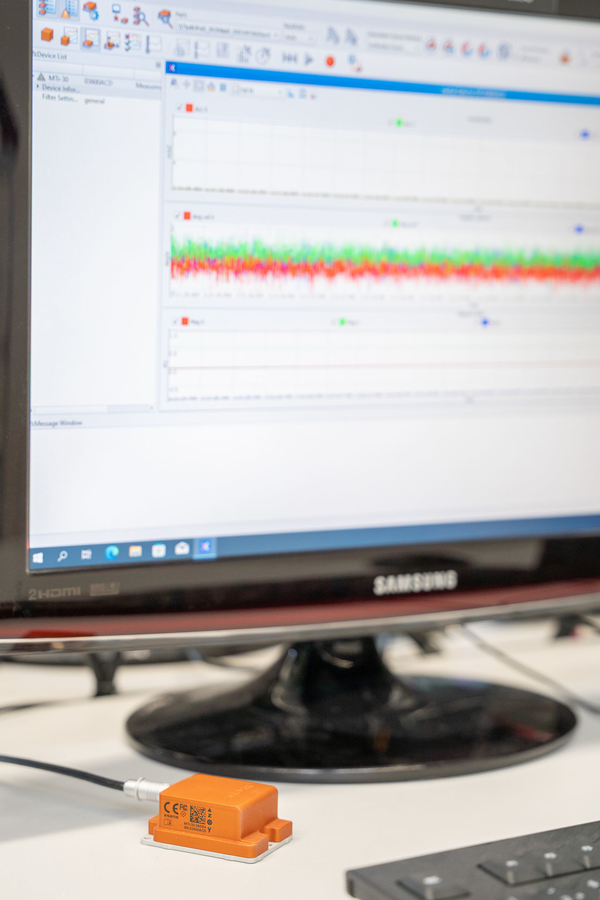

In terms of infrastructure, the research group relies on powerful AI servers for algorithm development and simulation, test bed environments for automotive Ethernet, for example, and, as planned, high-precision driving parameter measurement technology. This enables studies in the areas of driving function precision, homologation, user experience (UX) and usability.

The research team's work covers almost all areas of autonomous driving as well as the further development of driver assistance systems.

Current work includes in-vehicle big data analytics systems for the development of data-based algorithms with the help of intelligent edge nodes. In the INSTATE funding project, metadata is already being generated in the vehicle with the help of intelligent edge devices. These are connected to a vehicle's sensors. The metadata generated in this way can be used by a big data platform to understand the current scenario. In addition, data, including metadata, is only recorded as needed.

- Data-driven algorithms for autonomous driving using intelligent edge nodes

- Metadata generation directly in the vehicle

- Conversion of sensor data into compressed streams

- Backend connection via 5G gateway

The INSTATE project aims to use AI methods to explore new ways of recording and processing sensor data.

Work on innovative safety concepts for the start-up capability of the entire vehicle was recently completed as part of the iAATG project. Among other things, research was conducted into the detection of specific events based on high functional/system complexity using artificial intelligence methods (single event analysis). Furthermore, work was carried out on the validation of automated driving functions using inductive test strategies for ‘vehicle integrated testing’ (Vitbox), as well as research into the validation and verification of backend interaction with regard to automated driving functions.

- single event analyse

- Vehicle integrated Testing

- Backendinteraction

The iAATG project is researching innovative strategies for ensuring the safety of autonomous driving functions.

Student projects

An essential part of Prof. Thomas Limbrunner's research group is the collaboration with students on student projects and theses. Within these projects, a wide variety of sensor systems are put into operation and connected, and the data is then evaluated and analysed.

An important cooperation here is the collaboration between TC Plattling and the ‘Master of Applied Research’ degree programme.

Example of an IMU (inertial measurement unit)

Example of a master's thesis: simulation-based data generation and evaluation

In addition to evaluating real data, the research work also focuses on simulation-based training data generation for image processing using artificial intelligence.

Overview of equipment

- GPU-supported Kubernetes cluster for AI development

- Various workstations (additive manufacturing, electronic assemblies, lifting platforms, etc.) for the implementation of prototype assemblies for research

- Automotive Ethernet test bed for stress tests and time synchronisation

- 5G campus network

- ADAS measurement technology with reference sensors

- Development and test equipment for vehicle bus communication

- Monitor HiL and ADAS simulation environment

- Various mobile autonomous platforms for sensor and function development

- GNSS - RTK reference station

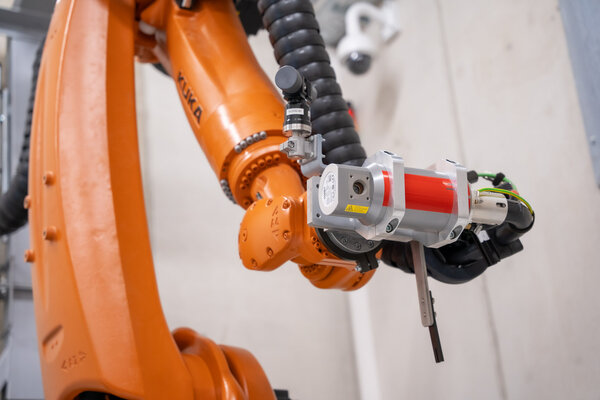

The Robo-CT department headed by Prof. Dr. Simon Zabler conducts research into the 3D digitisation of large objects, including entire vehicles, using a robot-based digitisation cell based on X-ray computed tomography.

- Multimodal non-destructive testing with optical measurement and X-ray technology

- Automated 2D & 3D X-ray inspection of large, industrially relevant objects

- Flexible three-dimensional positioning

- Collision-free, automatic robot movement

- Research focus

- Computed tomography-based, collision-free trajectory optimisation

- Precise positioning and calibration of X-ray components

- Data completeness of scan trajectories

- More use examples

Exemplary, current challenges

- Optimisation of object placement to avoid inaccessible areas

- Determination of the necessary degrees of freedom for robot movement

Overview of equipment

- Robots: 2 KUKA KR 120 R2900 extra on the linear axes ‘KUKA Linear Unit KL 4000’

- Heavy-duty table: WEISS – CR1000C

- X-ray source: Comet - XRS-225VF

- X-ray detector: Varex Imaging – PaxScan 4343DX-I

- Laser tracker: API – Radian

- 3D scanner: Photoneo – PhoXi 3D Scanner

Robot with X-ray detector

Robot with X-ray source

Current projects

SmartCT

The SmartCT project develops and applies AI methods that enable robot-assisted computed tomography systems (robot CT) to autonomously and non-destructively capture the external and internal structures of any object. The data generated forms the basis for novel, innovative and data-driven business models in many areas, such as product development (vehicle components, aircraft wings, battery cells, etc.).

X-ray image of an e-bike

Projects

One focus of the Deggendorf Institute of Technology (DIT) is applied research and development. The close cooperation with partners from business and industry guarantees industry-oriented research. In contrast to the classical basic research at the universities, the main focus is on application results up to the prototype phase as well as the implementation and utilisation of the research and development results.

The research and development offers at DIT:

- Research and development cooperations between companies, institutes and universities

- Research within the framework of public funding programmes

- Contract research and development for the KMUs

- Services and studies within the scope of university projects

- Development of innovative technologies, products and ideas

- Individual projects

- Cooperation in "clusters"

The research activities for innovative solutions, going far beyond the automotive sector, build on the previous research activities of DIT. Further projects in the research area of Innovative Mobility are being carried out at the Technology Campus Freyung.

Directions

Technische Hochschule Deggendorf

Technologie Campus Plattling

Forschungszentrum "Moderne Mobilität"

Werkstraße 17

D-94447 Plattling

Germany

| Postanschrift: |

Werkstrasse 17 94447 Plattling Germany |

| Telefon: | +49 991 3615 8600 |

| Fax: | +49 991 3615 297 |

| E-Mail: | tc-plattling@th-deg.de |